The term Ultra-Low Energy Building is used for buildings with a primary energy consumption for heating, cooling, ventilation and hot water, between:

• 20 to 40 kilowatt-hours per square metre per year (kWh/m2 TFA/year) for cold and temperate climate zones,

• 25 to 50 kWh/m2 TFA/year for hot and arid climate zones and

• 50 to 100 kWh/m2 TFA/year for hot and humid climate zones (where additional dehumidification is required).

The corresponding final energy consumption for fuel (gas, oil or biomass) and electricity must fall significantly below these limits.

In India, it is possible to design an Ultra Low Energy building using the ICF technology that meets requirements of energy efficiency, say 25-50 KWh/m2/year for hot and arid, Delhi. Calculations will show a building energy consumption of 32 KWh/m2/year for cooling load with 150 days of AC operation as against 315 KWh/m2/year consumption for conventional buildings. Most important, this design is with a basic ICF system of 50mm Insulation on both sides of 150 mm concrete.

What is ICF?:

The word ICF is an acronym for Insulated Concrete Forms (Shuttering). It uses 6 different hollow, ultra lightweight Polystyrene foam, interlocking blocks. These can be easily stacked up to 3m height and horizontal reinforcing steel laid in each layer. This form work is inclusive of door and window openings.

Earthquake Proof ICF:

After creating a perfectly straight shuttering (supported and straightened using a special scaffolding system called “Trestles”) we can pour Concrete into the hollow portion of the shuttering. This will create the load bearing, monolithic concrete walls. These walls join on all edges and the roof, give the building a steel reinforced concrete 3-D Box structure which is very strong in all disasters like earthquakes, tornadoes, floods etc.

Fireproof ICF:

The ICF Blocks are made of Self Extinguishing quality polystyrene foam and are in dovetailed integration with the concrete poured inside. The insulation layers on both sides of the building are covered with highly fire retardant layers of fiberglass reinforced polymerized plaster. This combination provides the building with 3-4 hours of fire rating.

.Energy Efficient ICF:

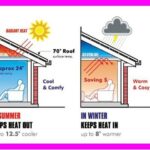

These concrete walls have 5 air barrier layers. There are 2 layers of polystyrene foam, 2 layers of polymerized plaster on top of them and 1 layer concrete. This arrangement gives the house a great thermal resistance value starting at R-19 and very low air leakages measuring 0.5 ACH(Air changes per hour). The heavy weight concrete of these walls give very high thermal inertia to the building. This prevents the external temperature fluctuations from reaching the living space by up to 12 hrs.Thus ICF buildings have:

- Very High thermal resistance value starting at R-19 as against R-1 of conventional, brick-mortar buildings.

- Low air leakages measuring 0.5 ACH(Air changes per hour) as against 10-12 of conventional buildings.

- High thermal inertia of the external walls.

These properties of ICF buildings make them very high in energy efficiency.

Low Cost ICF:

These buildings are being delivered at disruptive prices in India. The labor component in erection of these buildings being significantly less, ICF is able to compete quite well with conventional technologies in cost terms. Especially so, since these buildings come up in less than half the time, reducing the interest and alternate accommodation cost by more than half. Low income PMAY buildings are using this technology, indicating the overall competitive pricing of the ICF technology.

Thus on an overall assessment basis, the ICF technology for constructing buildings can reduce energy requirements of the future buildings being constructed very significantly. Assuming the Government target of 10 million EWS houses being constructed upto 2022 of say 30 sqm floor area each. Then using conventional technologies, it would be adding 66 sqm of walls and 30 sqm of roof i.e. a total of 96 sqm of which say 40% is maintained at a comfort level, there would be an additional load of 96sqmx40%x315KWhr/sqmx100000000 or 12×1011 units per annum on the grid i.e 137000 MW power additionally required. However if the same buildings are made with ICF the additional load can be calculated as 14000 MW only. However these are just back of the envelope calculations for ideation and need to be modelled properly with average weather conditions of the building distribution geographically to get a final picture.

Pingback: A brief(-ish) history of ICF — Greener, Safer, Stronger, Faster Construction